Contract Electronics Manufacturing Services

Our Electronics Manufacturing Services

If you’re looking for the a true partnership, with all the capability in terms of design and manufacturing we believe BitBox is the right partner for you. From design and specification to manufacture and compliance, BitBox has all the expertise you need.

BitBox is a leading UK Electronics Manufacturing Service provider. With both our HQ and manufacturing facilities based in the UK, we offer end to end contract electronics manufacturing including electronic product design, PCB assembly, box build, supply chain management and consultancy services

Quality isn’t optional. It’s obligatory.

Our proven manufacturing process

At BitBox, we have specialised knowledge and experience in electronic manufacturing processes. Our Printed Circuit Board (PCB) assembly expertise includes sensors, power management systems, gateways, PLCs, microcontrollers, Internet of Things (IoT) devices, lighting management systems and more.

Our Approach

We combine creative problem solving with rigorous engineering expertise - applying financial discipline, speed and meticulous attention to detail throughout.

Quality Assurance

Our Process

Our tried and tested processes and approach to continuous improvement result in consistency at every turn for our customers, ensuring peace of mind by formally documenting every process and procedure in our ISO 9000 quality management system.

Aftercare

Aftercare is an integral part of our service - as is open, honest and friendly communication. Our dedicated customer care team ensure all your aftercare needs are met.

Explore our electronic manufacturing capabilities.

The latest technology means nothing without the right people. We invest in both. That’s how we optimise our production line to meet the demands of every job. Our current plant includes:

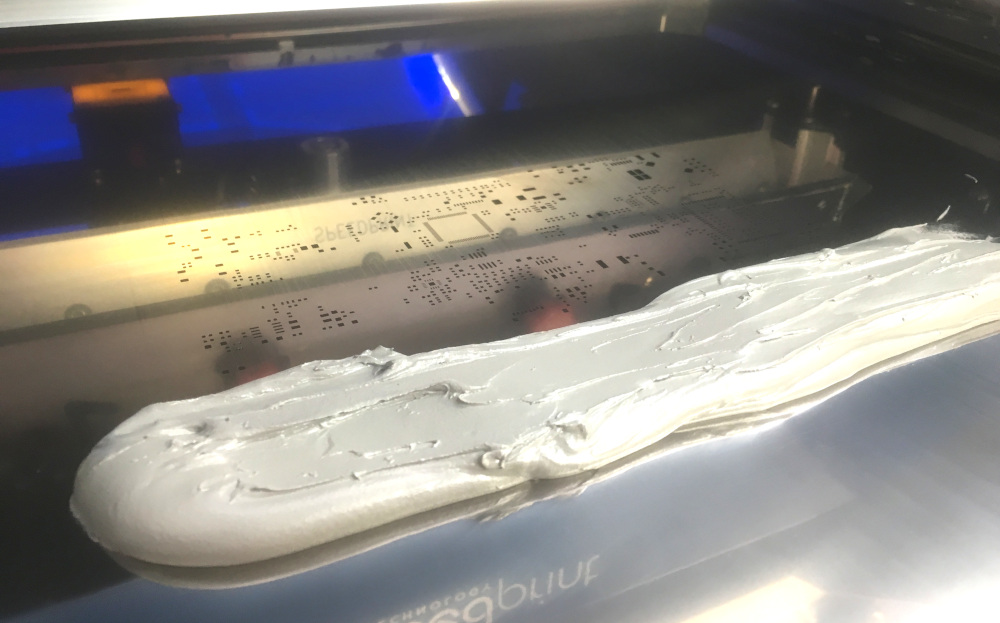

Speedprint SP710avi

Max board size 600mm x 510mmAutomatic optical alignment to 20um @ 6 Sigma 2cpkAutomatic speed and pressure control for squeegee operation2D+ solder paste inspectionAutomatic under-stencil cleaner

8 Zone Reflow Oven

Manufacturing Plant: 8 Zone Reflow Oven8 heating zones top and bottom 2 cooling zonesHeated length 2.2mConveyor speed 0.3 – 1.6m/minChain conveyor with anti warp supportTemperature accuracy ±1ºC

Umo-390 PCB Stacker

Manufacturing Plant: Umo 390 PCB StackerPCB unloader mechanism3 off R-808 racks (535 x 460 x 570 mm)Max PCB size 535 x (50-390mm)

Optical Inspection System

Manufacturing Plant: Optical Inspection System4M pixel colour CCD camera providing 10.6µM resolution suitable for 01005 components Telecentric Lens to ensure no distortion of image. Laser Co-planarity capability for BGA and IC lead inspection (automatic lead height profile) now providing the highest level of performance from a bench top AOI system; as standard Standard inspection area 470mm x 450mm3 tier coloured LED lighting for accurate solder inspection Database connectivity for statistical reporting Off-line software included for programming and rework facility

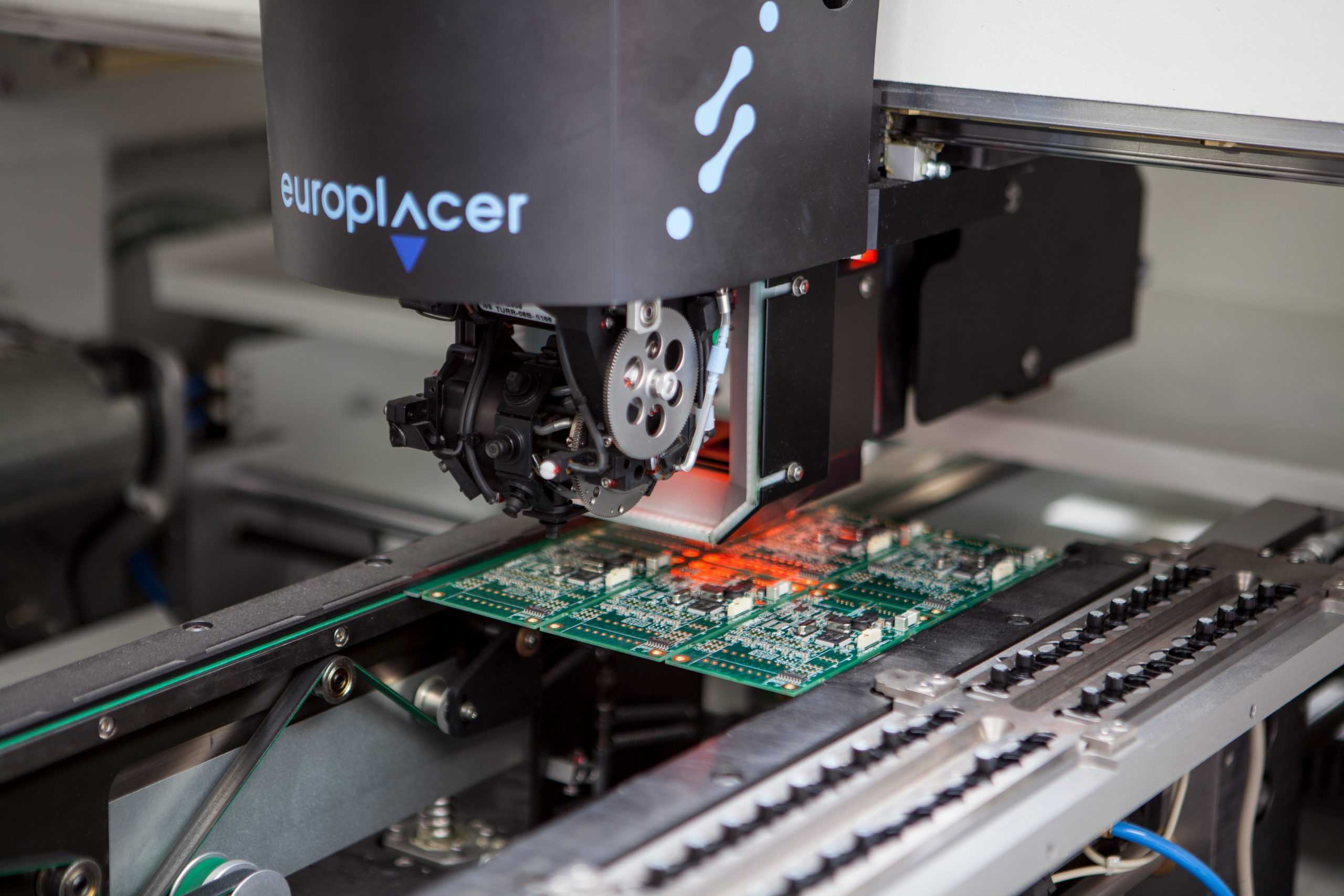

Europlacer iineo 2

Manufacturing Plant: Europlacer Iineo 22 rotary heads on dual linear X/Y gantries with 8 and 12 pick ups & a 40 position ‘smart’ nozzle bank per headPlacement rate 26,300 components per hourComponent placement from 01005 to 50x50mmComponent lead pitch 0.3mm (QFP), 0.4mm (µBGA)Component lead size 0.15mm (QFP), 0.2mm (µBGA)Accuracy, standard 35µm (QFP) to 50µm (Chip) up to 264 8mm feeders plus 3 Jedec traysMax PCB size 700 x 460mm