Our Design Process

Electronics Design

Electronics Design Entrust your new application to our world-class electronics engineers

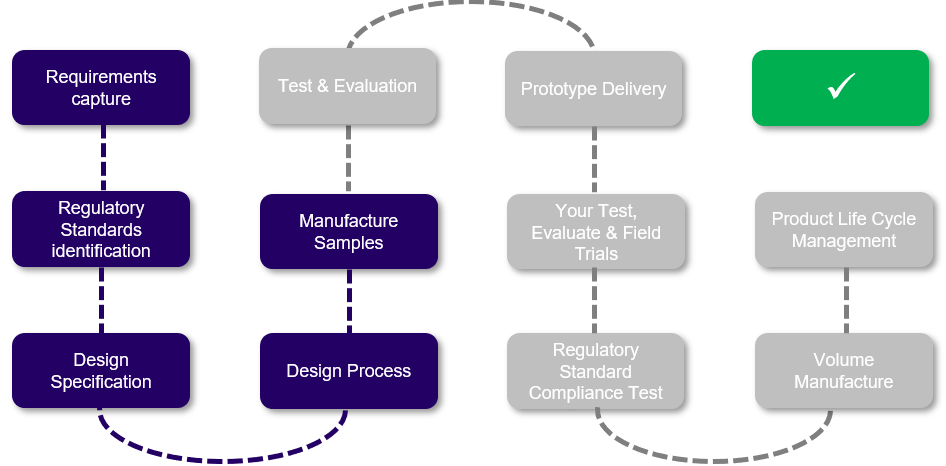

Proven Design Process

With over 25 years of experience, we know what works and what does not when it comes to design. Our proven design flow process for taking products from concept to reality has been tested over time and with thousands of devices.

Our design process protects your company and reputation by following our proven development flow process to create a product that is built to last and one which meets the brief you have set.

Thousands of BitBox devices are out there

You may not see them but there are thousands of successful BitBox devices in the field right now. Each one is testament to the quality of our design process. We combine creative problem solving with rigorous engineering expertise.

We’re the experts in electronics design and manufacture. But only you’re the expert in your business. That’s why our process is consultative and highly collaborative. It starts by learning as much as we can from you about your product, your business and your objectives. Only then do we apply our expertise to turning your vision into a reality.