An Engineer's Guide To Understanding the Electronic Product Design Process

Discover a breakdown of the electronics design process with BitBox

How does understanding the electronics design process help your project?

Understanding the electronic product design process can help your business to manage the commercial elements of new product development. In this article we will break down the steps involved in going from an initial idea right the way through to final commercialisation and volume manufacture.

Without a full understanding of what each different stage includes you may be put in a position where you think you have a production ready product, but in reality, you only have a pre-production prototype. This can cause lengthy delays, tough questions raised by financial backers, and damage to your company reputation with your customers.

By the end of this article, you should be able to de-risk the process and know the correct questions to ask your design partners.

A breakdown of the product design process – What you need to know

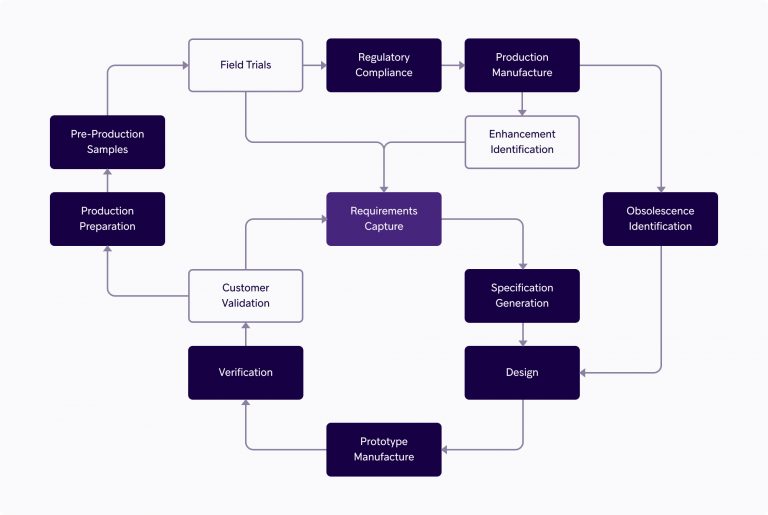

The diagram below shows the full product design cycle that we use at BitBox. Using this methodology results in a faster overall time to market with lower levels of specification creep and minimisation of unexpected delays during your project.

Requirements Capture

Requirements capture involves BitBox working with you to extract the technical requirements of your product. This process can help you as a customer to clearly define exactly what you would like your product to look like and how you would like it to operate.

The output of this stage of work is a document called a Product Requirements Document (PRD) and it helps to crystalise exactly what we are looking to design together.

Specification Generation

Specification generation is where BitBox takes the PRD and generates an in-depth specification which will detail exactly how the product would be implemented.

This would include in depth hardware details such as the parts that will be used for each interface on the product and the shape, size and materials that would be used in the enclosure to get the look and feel that your users require.

Another major part of this document is the fully detailed software specification that would describe any user interfaces and protocols that are to be used on the product.

The output of this stage of work is a document called the Functional Specification Document (FSD). At this stage we can also estimate the product cost to ensure that it is aligned to your commercial requirements.

Design, Prototype Manufacture and Verification

This is the stage where we start to turn the details in the specification document into a physical product. This starts with the project being handed over to our hardware and software engineers who begin work on the Schematic, PCB Layout and Software.

As we progress through this stage, we hold design review meetings with you at milestone points such as the end of schematic design and when all the components have been placed on the PCB layout. This allows you to see exactly how the project is progressing and ensures you can see exactly what the product will look like in a virtual environment.

Once the PCB Layout is completed a manufacturing package is created which we then hand over to our in-house manufacturing team. They will then manufacture the product and return it to the engineering team.

The final element of this stage of the design is to perform the verification of the product. This is where the BitBox engineering team will take the product and test every element of it against the FSD document to ensure that it meets the agreed specification.

Once this is completed the prototype product is shipped to you.

Customer Validation

Validation is one of the most important steps for our customers. Customers must exercise the prototype in all its use cases and ensure that the device meets its intended purpose, operating in exactly the way required.

With a suitable amount of time spent upfront during the requirements capture stage of work this is normally a relatively painless process.

Compliance

Depending on the country you wish to sell your product into there will be various marks that need to be applied to show your product is compliant. These can include UKCA, CE and UL marks.

Each of these marks generally requires an element of Electromagnetic Compatibility (EMC) assessment and safety assessment to ensure that the product won’t interfere with or be affected by other electronic devices and that it is safe to use. To satisfy these requirements our engineers work with accredited test houses to perform testing and generate reports to prove compliance.

A Technical Construction File (TCF) is generated to pull the information in the test reports together. This is combined with compliance information from the manufacturing side such as RoHS and REACH. Customers use these as a central repository for all the compliance information about their product. Customers can make this available to any market enforcement bodies upon request. It also offers peace of mind that a product complies with the required standards.

Pre-Production Samples and Field Trials

The next stage in the process is to generate several pre-production samples for trials with your customer base. This is the stage where you get large scale feedback from your customers to evaluate how the product works for them. Sometimes this will generate a list of enhancements that they might like to see in the product. It is then your commercial decision whether you implement these features now or if you use them for a later version of the product that you can market at an enhanced price point.

Production Manufacture and Product Life Management

The final stage of the process is to start volume manufacture of the product. BitBox can help guide you through this stage and then offer support with issues around part supply and obsolescence as the product matures.

Visit our Electronics Design Page

Unlock the Secrets to a Profitable OEM Strategy!

Dive into our FREE PDF guide and discover strategies that can transform your OEM purchasing. From strategic foresight to risk management, get insights that set you apart.