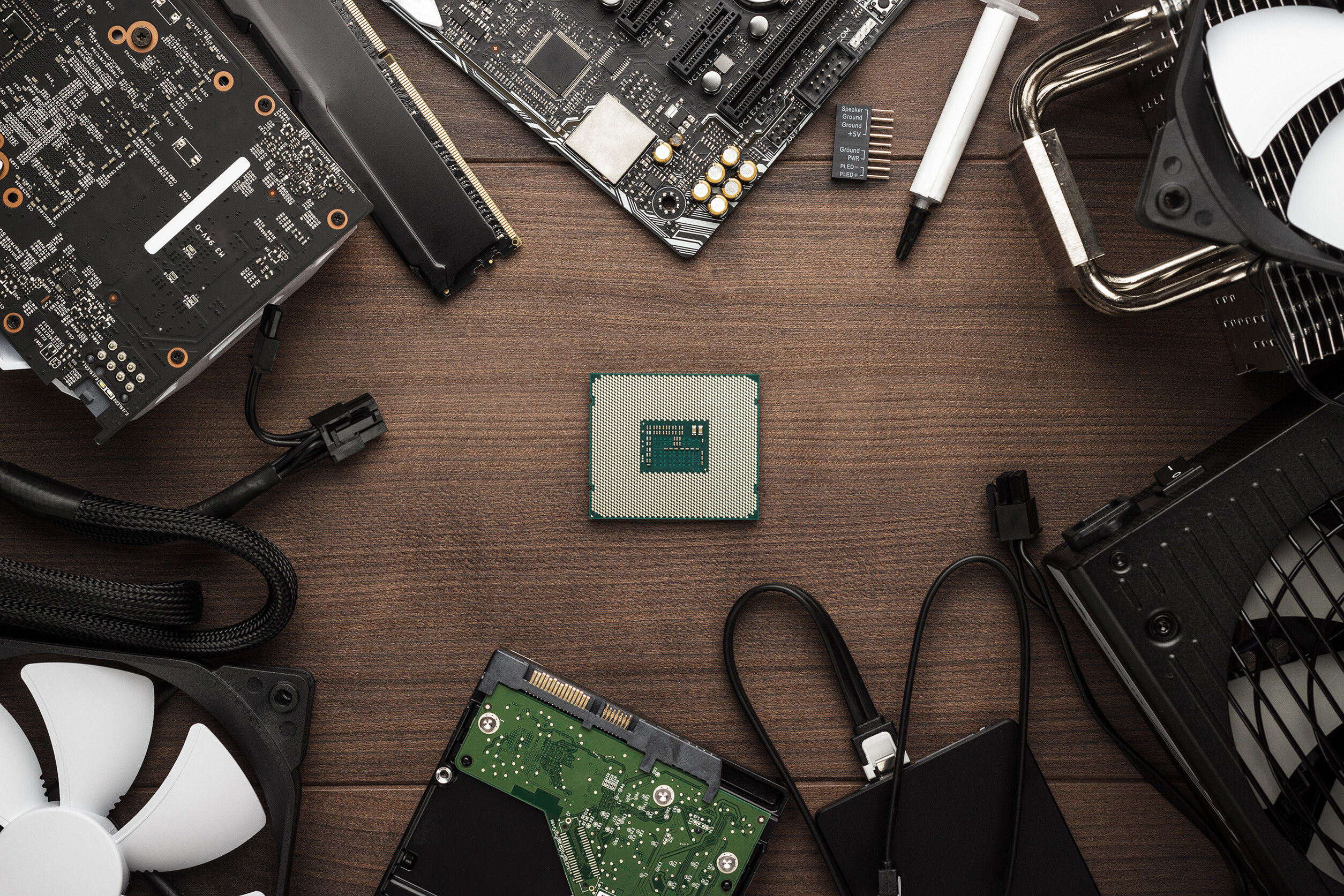

Ensuring long-term reliability & performance

At BitBox, we believe in building electronics that stand the test of time. Life cycle management isn’t just about dealing with obsolete components—it’s about proactively safeguarding the longevity, reliability, and efficiency of your product. We take a hands-on, partnership-led approach to ensure that every product we manufacture remains viable, cost-effective, and future-proof.

A proactive approach to product longevity

Electronic components don’t last forever. Changes in technology, shifts in market demand, and evolving regulations can render critical components obsolete. Without a structured approach to life cycle management, your product could face production delays, increased costs, or even failure in the field.

At BitBox, we don’t wait for obsolescence to become a problem—we anticipate it. By continuously monitoring your Bill of Materials (BoM), we identify potential risks early and implement strategic solutions to keep your product performing at its best.

Production delays

An essential component becoming obsolete can disrupt supply chains, causing costly setbacks.

Increased costs

Finding last-minute replacements or redesigning a product can drive up expenses.

Product failure

Using outdated or unsuitable components can lead to operational issues and failures in the field.

Reputational damage

Product recalls or failures can impact customer trust and market position.

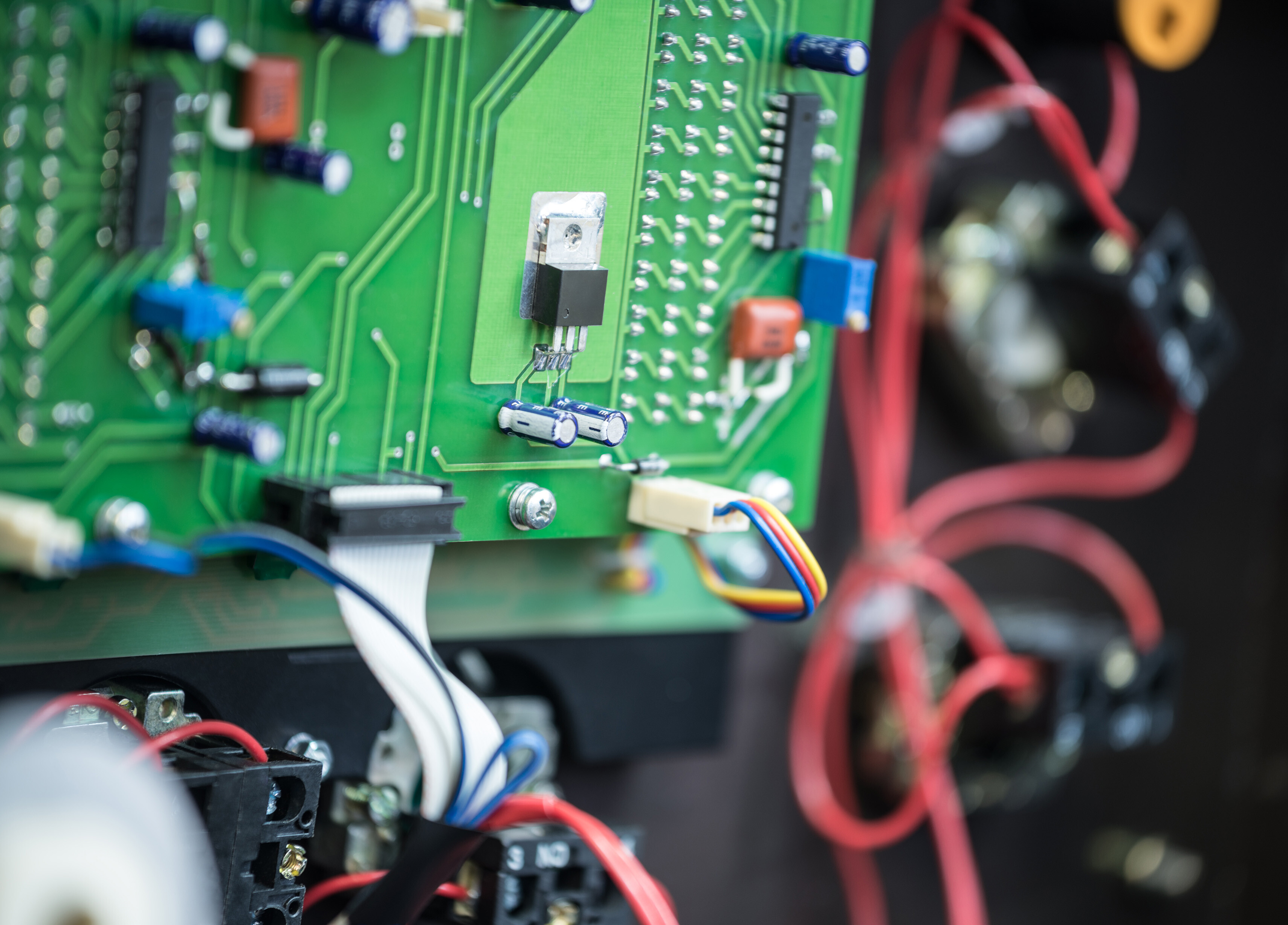

How we manage component life cycles

BitBox provides a structured, expert-driven approach to life cycle management, offering tailored solutions based on your specific needs. Our engineering team takes full responsibility for ensuring the long-term sustainability of your product when it has been designed in-house, and we can extend that service to your designs as an optional service.

If BitBox is the Design Authority:

- We continuously monitor the status of every component in your product.

If a Product Change Notice (PCN) is issued by a manufacturer, our team immediately assesses its impact. - We prioritise finding footprint-compatible alternatives to avoid costly PCB redesigns.

- Where necessary, we identify and validate suitable replacements that maintain performance and reliability.

- We handle the entire process—keeping you informed while taking full responsibility for the solution.

If You are the Design Authority:

- We still take an active role in monitoring and identifying potential obsolescence risks.

- When we receive a PCN, we don’t just pass the issue to you—we assess alternatives and offer solutions.

- We collaborate with your team to validate and approve any necessary changes.

- Our goal is to make life cycle management seamless, reducing disruption and ensuring a smooth transition when replacements are needed.

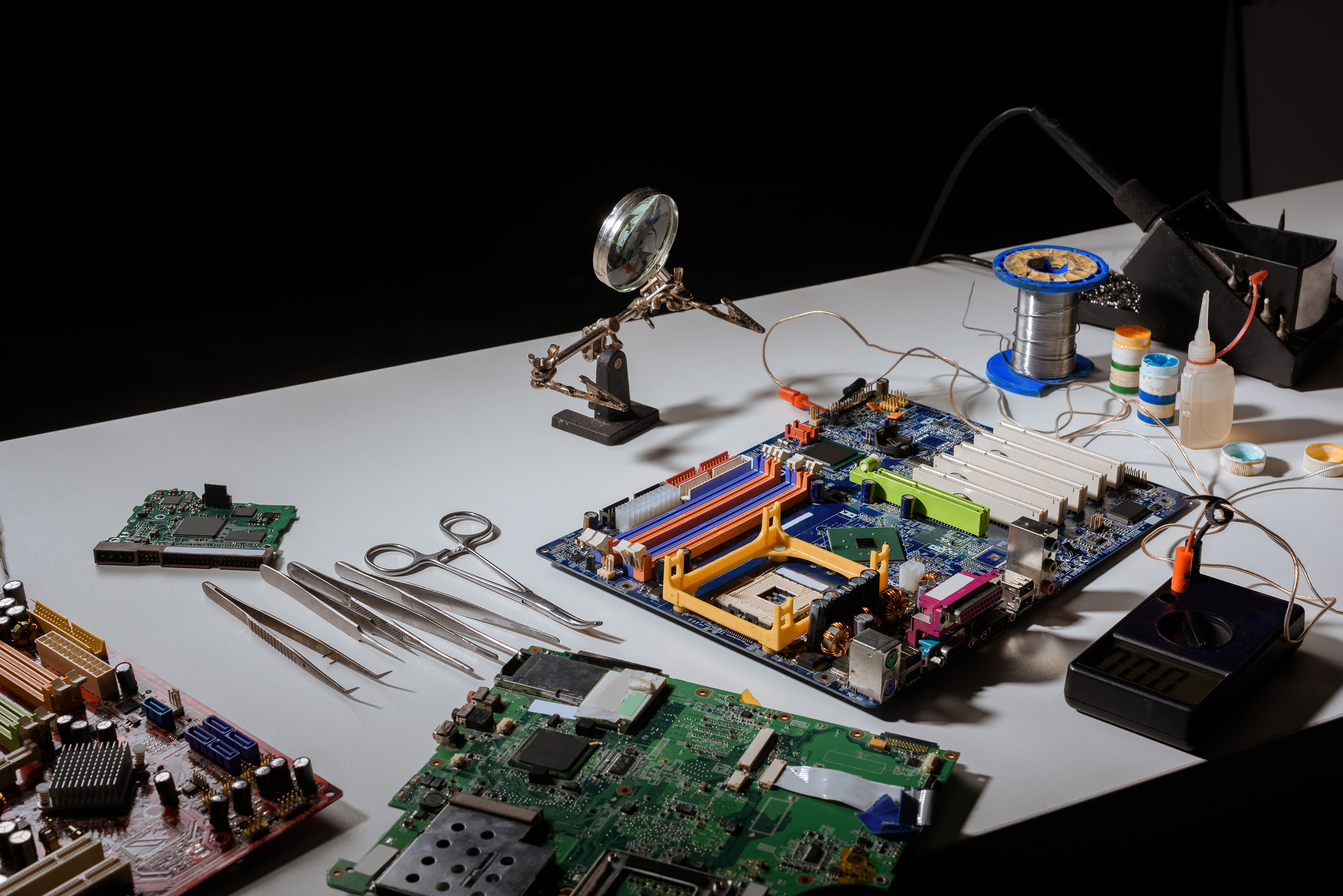

Free Bill of Materials Health Check

As part of our commitment to product longevity, we offer a complimentary BoM health check for both existing and prospective customers. Our team will assess your component list for potential risks and advise on strategies to extend product life and minimise future disruptions.

Industries we support

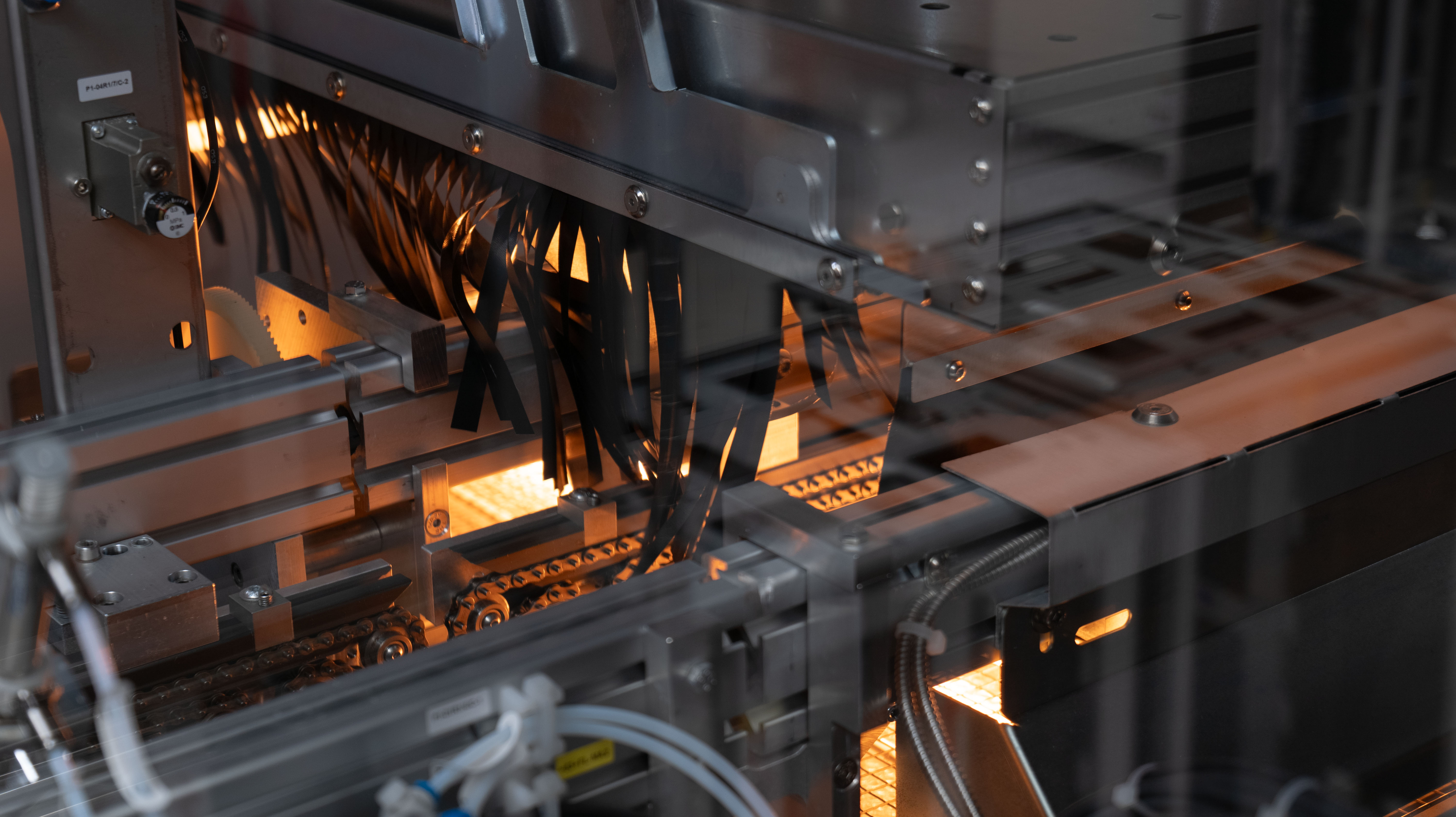

Industrial Automation

No matter your sector, we deliver precision, reliability, and innovation at every stage.

Automotive

Driving performance and reliability with advanced manufacturing solutions tailored for the automotive industry.

Scientific Equipment

Empowering research and innovation with precision-engineered solutions for cutting-edge scientific applications.

Consumer Electronics

Creating high-quality, user-centric products to meet the demands of today’s tech-savvy consumers.

IoT & Smart Technology

Enabling intelligent connectivity with robust, scalable solutions for the connected world.

Communication Electronics

Facilitating seamless connectivity with reliable, high-performance communication technologies.

A true partnership for the full product life cycle

At BitBox, life cycle management is more than a service—it’s a commitment to ensuring your product’s success over the long term. Whether you’re designing a new product or maintaining an existing one, we work as an extension of your team, taking responsibility for its reliability, scalability, and sustainability.